Pure Premium Quartz (PPQ) synthesis for SAW resonators beyond the state of the art

Background, Motivation and Objective

Quartz crystal is a key material for the development of the first generations of cellular phones with frequency filters operating in the 70-350 MHz frequency range with a quality factor times frequency (Q×f) products reaching values around 9×1012. Recent developments aim at developing low phase noise oscillator, taking advantage of the compactness, temperature stability and resonance quality of resonators built on the so-called AT-cut family defined using the IEEE Std-176 standard notation as (YXl)/θ with θ ranging from 28 to 40°.

As R&D on quartz has declined sharply in the past decades, the possibility to improve Q×f figures of merit as reported above was almost out of reach. Our team has relaunched R&D on high quality for couple of years, with success both in a new generation of autoclave, quartz crystal purity and larger size. Progresses have been made on wafer manufacturing too with a new technology of slicing.

In the present work, we present results obtained on PPQ wafers allowing for Q×f equal to 9×1012 at room conditions, thus potentially allowing for overpassing a value of 1013 under vacuum.

Statement of Contribution/Methods

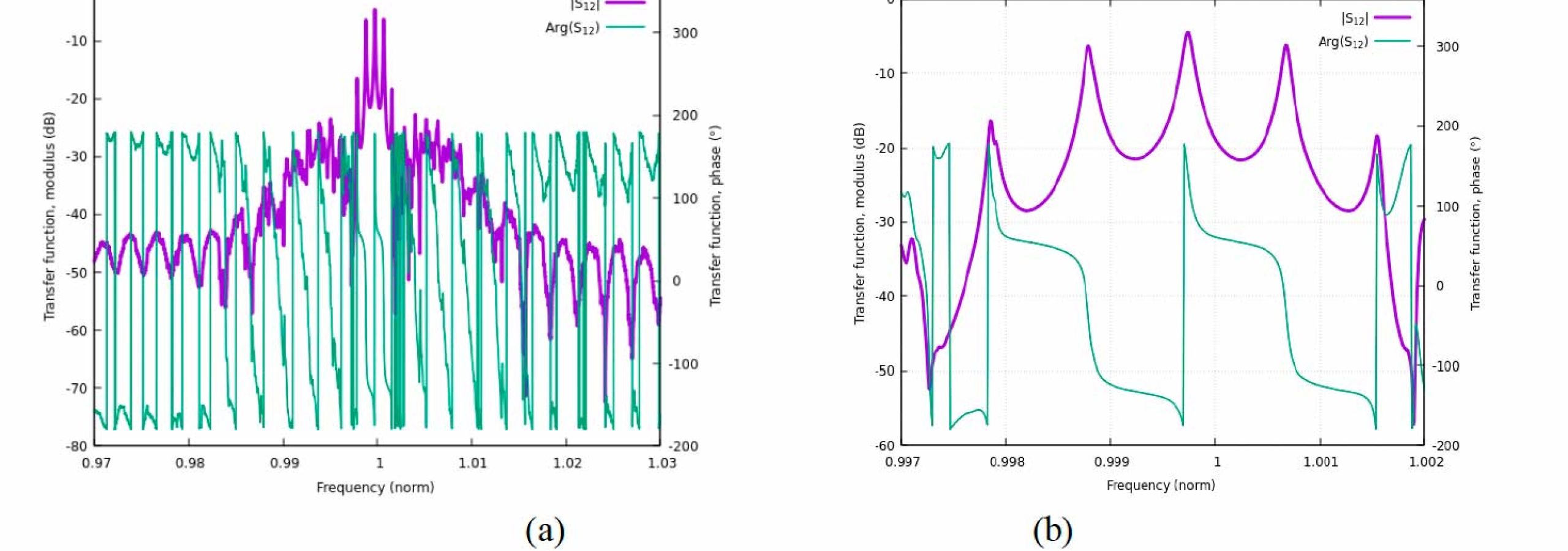

In the proposed work, we have developed an innovative Quartz synthesis process capable of providing a crystal with both characteristics, a very high quality (PPQ quality), and as large for 100mm AT wafering. This PPQ quality is characterized following IEC 60 758 and JIS C 6704, as the best grade on all specifications (Infrared absorption: α 3500cm-1 < 0,026 - Etch channels: Grade Ia < 5/cm² - impurity <100ppb). Our different examples of very high purity quartz crystals synthezised for producing 100 mm-diameter (4 inches) AT wafers were compatible with the industrial fabrication of SAW devices. Although rather brittle, the wafers have successfully passed the whole front-end process for the fabrication of multiple resonance resonators built using Al-Cu electrode gratings. Two interdigitated transducers (IDTs) operating out of the Bragg conditions have been used to pump and interrogate a resonance cavity limited by two Bragg mirrors optimized for limiting the overall length of the SAW resonator. The devices have been measured (a), (b) and compared with theoretical prediction, yielding an excellent agreement between both curves without material constant adjustment. The Temperature Coefficient of Frequency (TCF) was also measured and found exactly equal to what was theoretically predicted, once again using published material constants. Figures of merit are reported and the comparison with analysis has allowed for identifying an attenuation constant of 1 mdB/λ providing the measured Q factors and therefore a Q×f product of 8.96×1012.

Results/Discussion

Assuming that room condition operations yield an acoustic damping between 0.2 and 0.3 mdB/λ at frequencies below 1 GHz, we computed the Q×f product achievable with the new quartz wafers, yielding the possibility to overcome the barrier value of 1013, especially because R&D on quartz synthesis is still in progress, both on purity and size (150mm / 6 inches). Computation process and results are reported as a conclusion of the paper.