OUR TECHNOLOGY

Cutting services with high technological content (orientation, large size, 3D…) and characterization services.

Procces flow

Our Equipment

State-of-the-art equipment in crystal synthesis, substrate preparation and characterization.

Cristal Innov makes these pooled resources available to academia and industry in an environment dedicated to innovation and process co-development.

Our team

The expertise of Cristal Innov’s team covers all crystallogenesis technologies, with experience in both R&D and industry.

Our engineers and technicians master the different steps of TRL and they know how to lead a technology roadmap with you.

In production mode, Cristal Innov is part of ISO 9001 quality certification process.

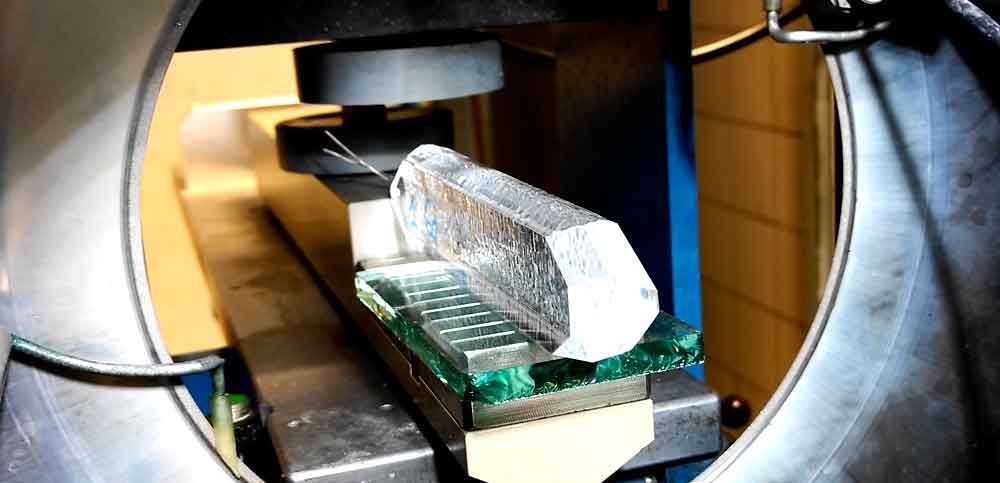

Cutting and shaping of hard materials

Technology services on hard and brittle materials (sapphire, SiC, various single crystals, ceramics, glass…)

Oriented cutting from 5 mm to 200 mm

- Diamond wire

- Internal Diameter sawing

Shaping up to 150 mm

- Surface and cylindrical grinders

- Lapping and polishing machines

Micro-machining

- Single wire saw

- Ultrasonic drill

Cleaning and inspections

- Automatic cleaning machine

- Inspections: see characterizations

Characterizations

Technology services

Crystalline quality

- Chemical purity (Al, Fe, Na, K, Ca<1ppm)

- Crystal defects: microscopic (etch channels, dislocation) or macroscopic (inclusions…)

- Crystalline quality factor (IR absorption coefficient)

Geometric and dimensional characterization

On substrates up to 200 mm, minimum thickness 200 µm

- Surface: Roughness - Ra 3nm

- Flatness - parallelism (0.5 µm accuracy), dimensional ± 5 µm

- Crystalline orientation: single-rotated or double-rotated (± 30 arc seconds accuracy)

Functional properties

- Elastic, piezoelectric and dielectric constants